Ideally, the air gaps need to be small enough to go unnoticed, yet large enough to fully clear the extrusion paths as the printer lays down layers. The holes on the ends of the leaves are just placeholders, as the main focus of this project is the pivot mechanism. Using a series of repeating reference planes, I cut out and extruded the interlocking knuckles, making sure to add an equal amount of negative space between both knuckles. I designed this hinge in SOLIDWORKS as one part file, separated into two bodies. Negative Space Based on Layer Thickness and Part Resolution The methods shown for this hinge design can be applied to almost any mobile or dynamic component that you design.

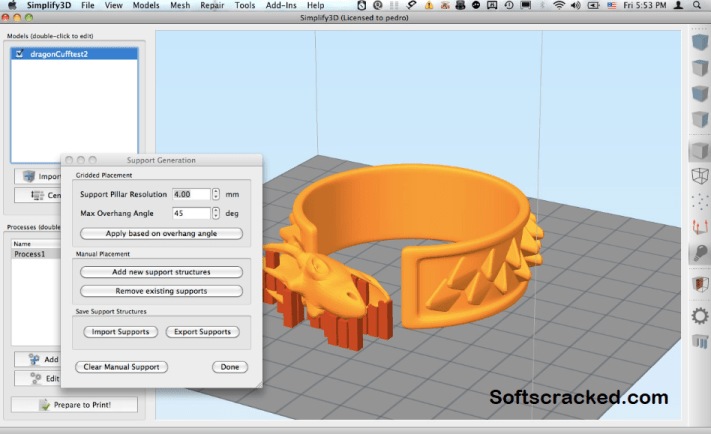

Hinges are usually comprised of the knuckles (the hollow portion of the hinge in which the pin is set), the leaves (the parts of the hinge that extend laterally from the knuckles and come in contact with the external surface), and the pin (the rod that holds the leaves together by being set inside the knuckles), but we’ll design and print the hinge as only two components. Screenshot of a custom hinge design comprised of only two moving parts

0 kommentar(er)

0 kommentar(er)